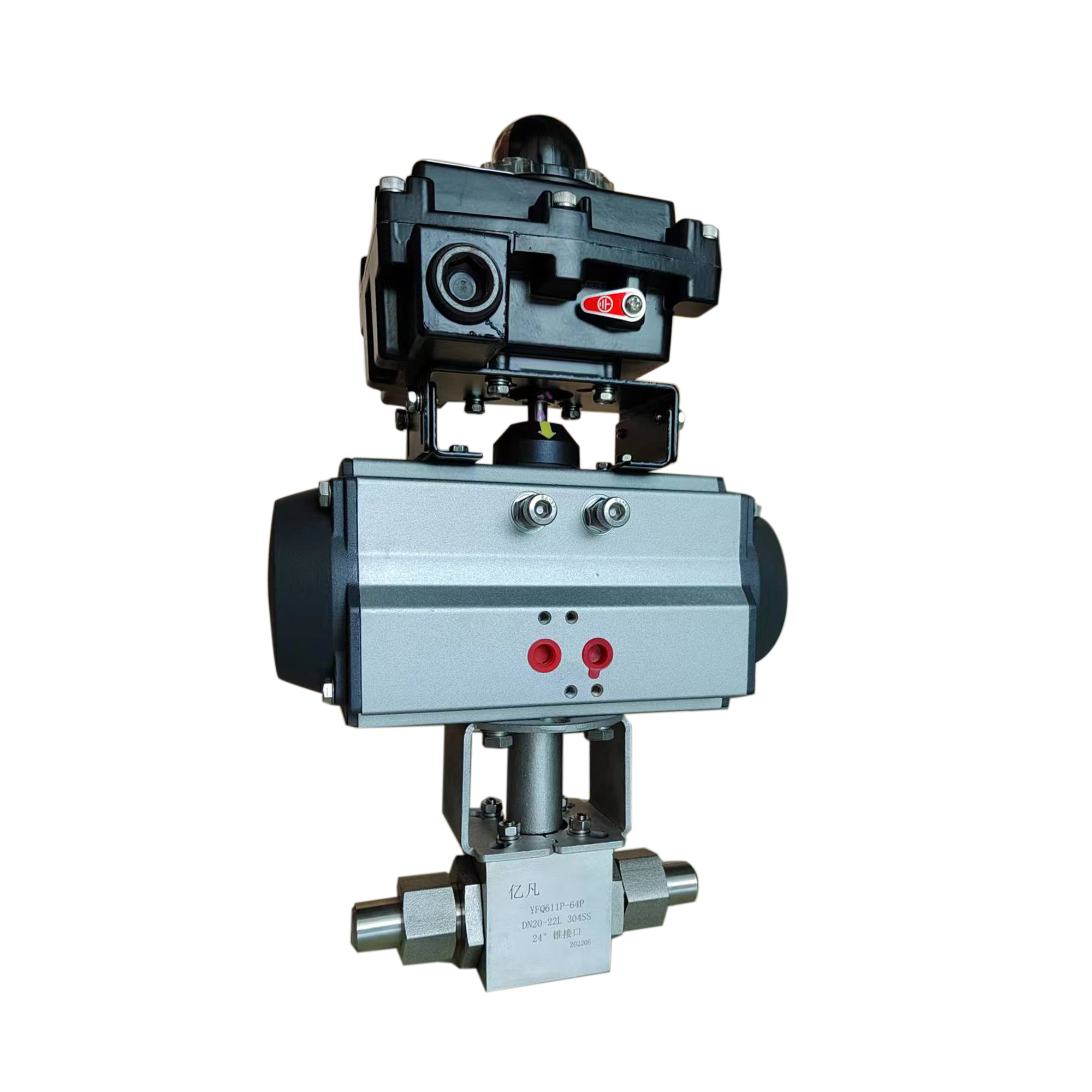

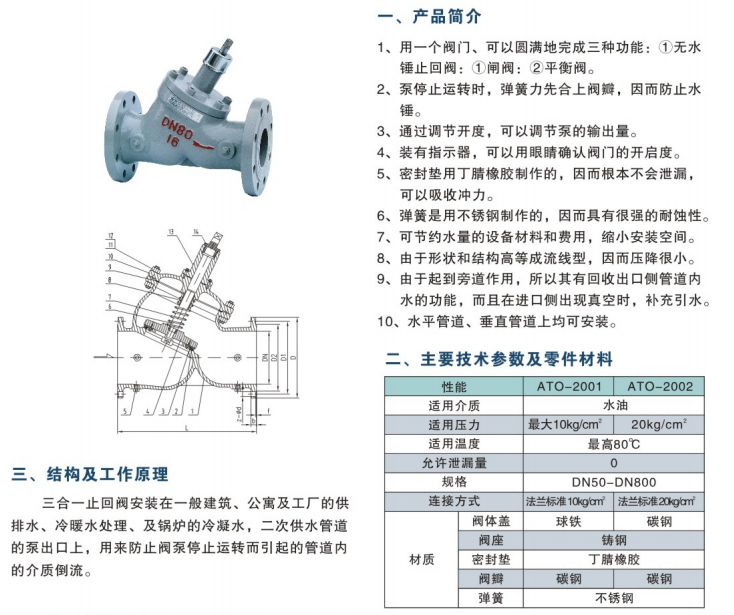

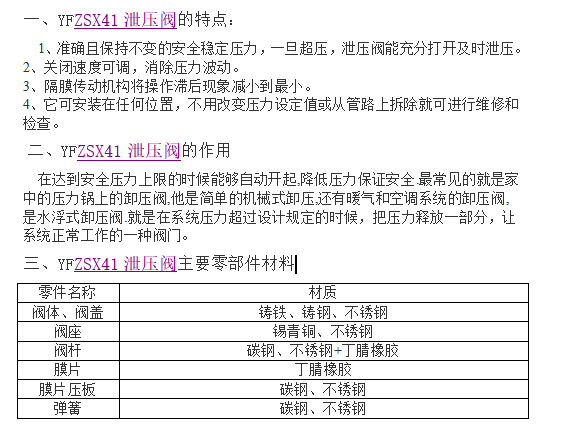

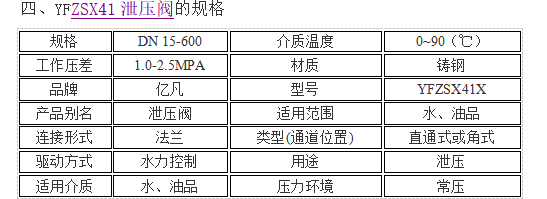

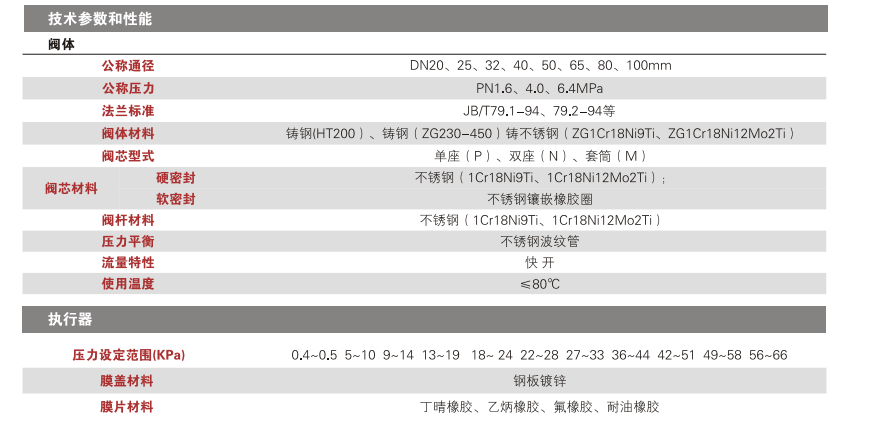

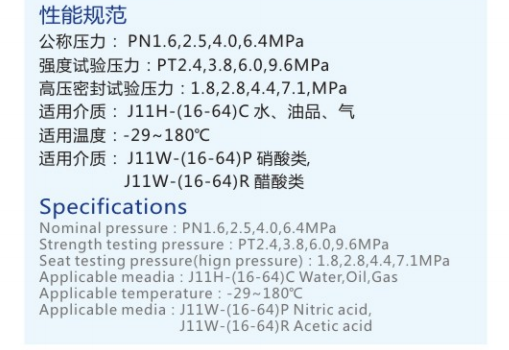

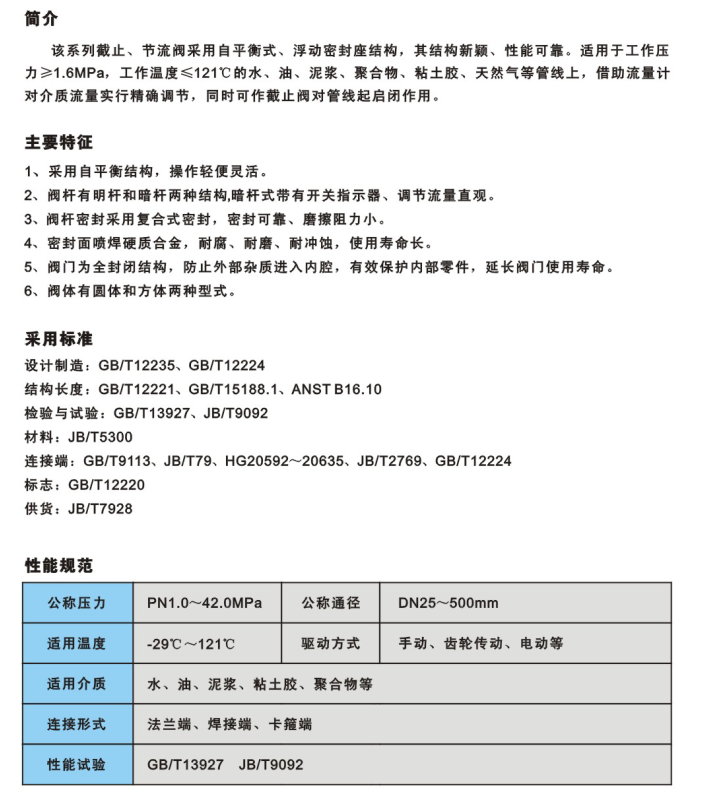

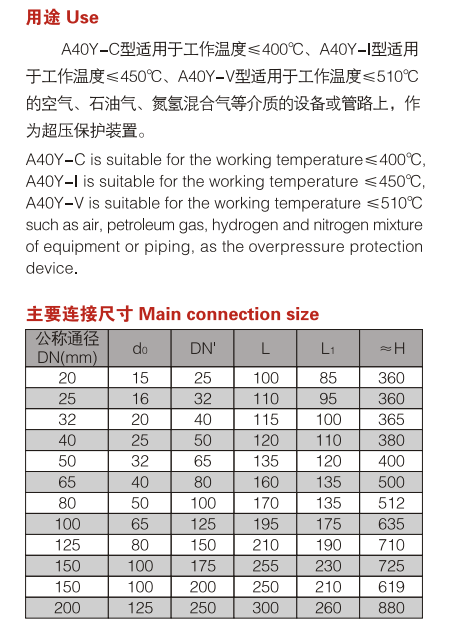

Product Name: Pressure Reducing Valve

Product model :YFYT-2

Product Specification :DW2-DN16

Nominal pressure :PN16-320

Valve material :304/316/316L, etc

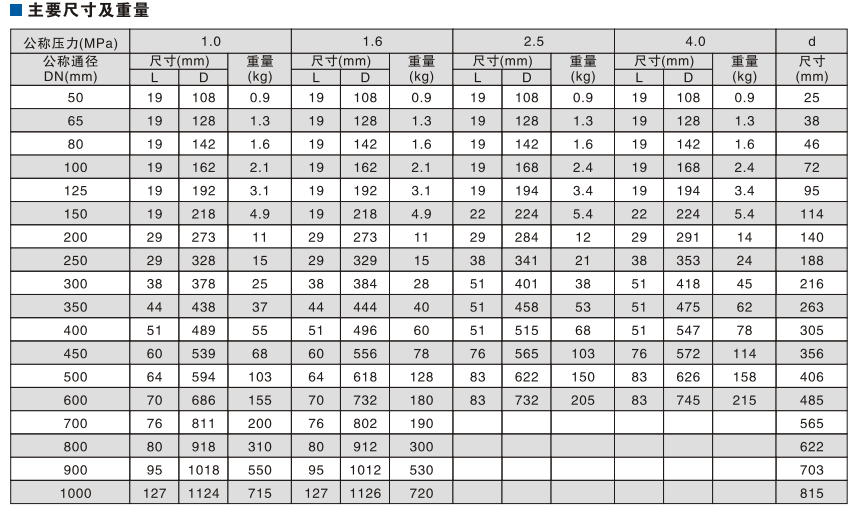

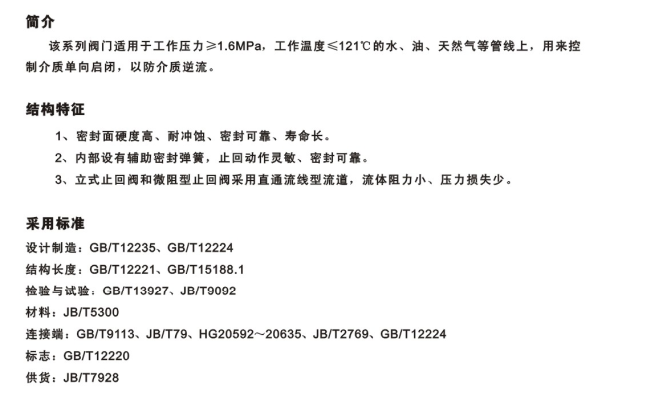

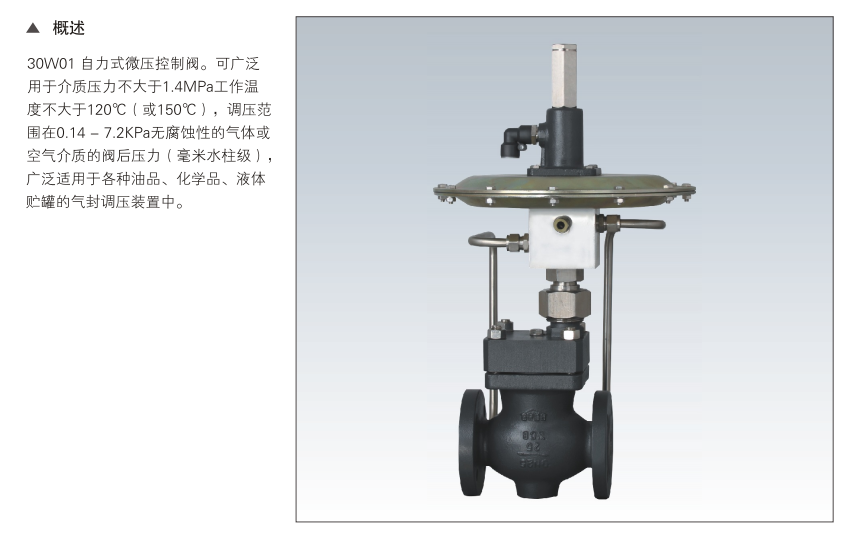

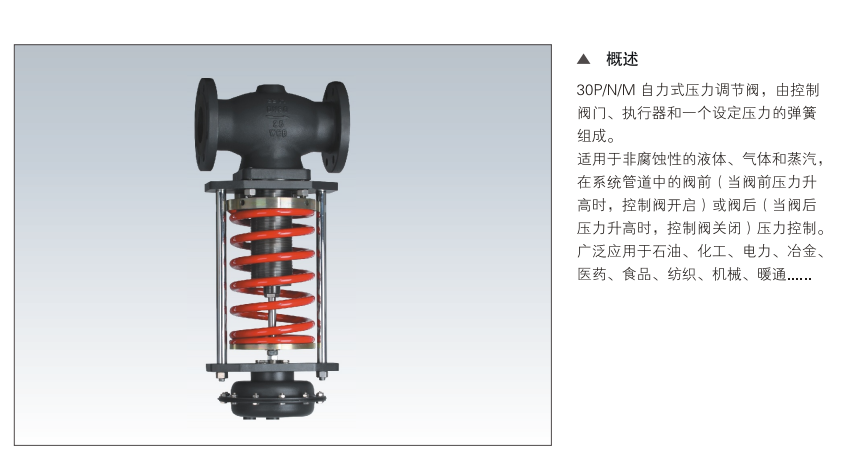

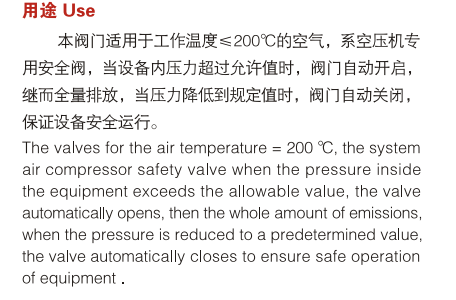

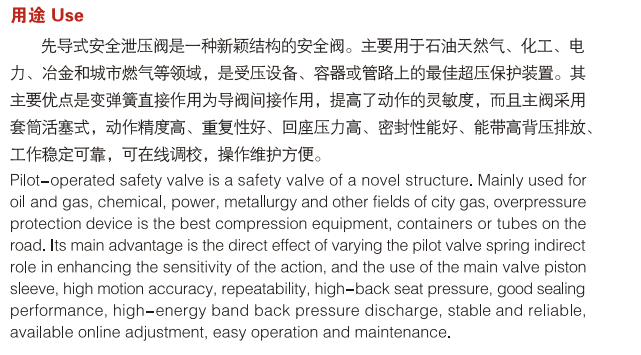

Overview of YFYT-2 Pressure Regulator:

The YFYT-2 type pressure regulator is a post-valve gas pressure regulator (commonly known as a pressure reducer), which can control the pressure of the subsequent device to a constant value.

The YFYT-2 type pressure regulator is designed and developed by our factory based on the characteristics and requirements of petrochemical scientific research facilities, integrating similar products at home and abroad. It features an attractive appearance, small size (the outer diameter of the valve body is 80mm), light weight (the total weight is 2.3kg), high pressure resistance, corrosion resistance, accurate pressure regulation, reliable performance, convenient maintenance and wide application range. It is suitable for regulating the gas pressure before the valve in medium and small-scale test equipment in the petroleum and chemical industries.

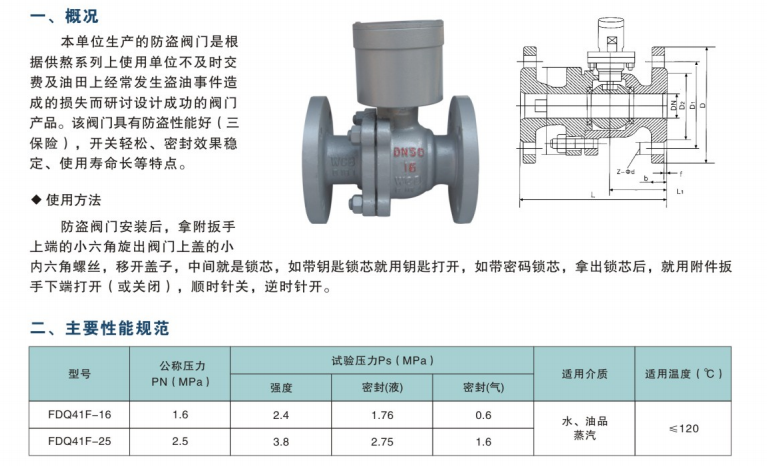

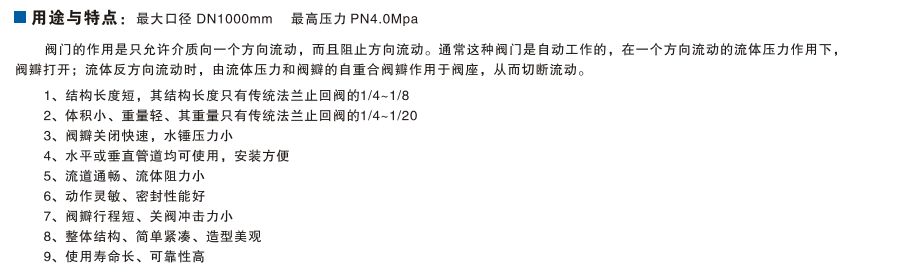

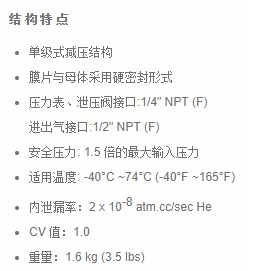

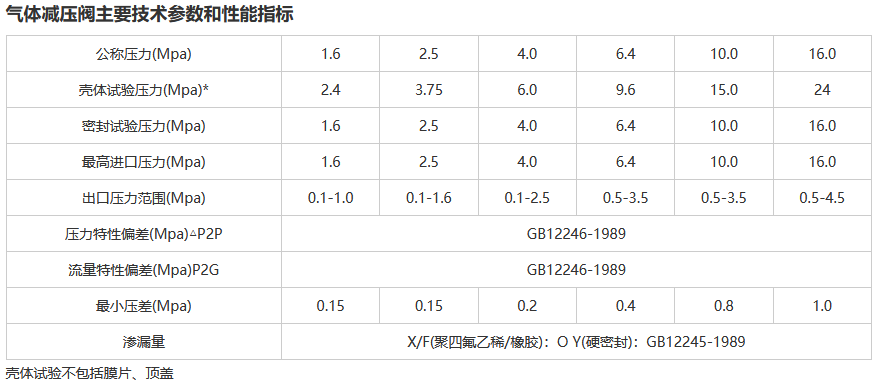

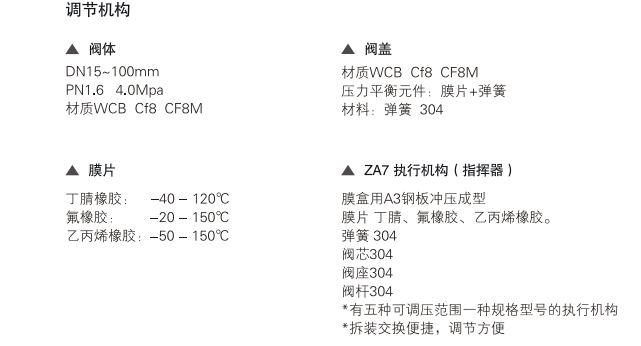

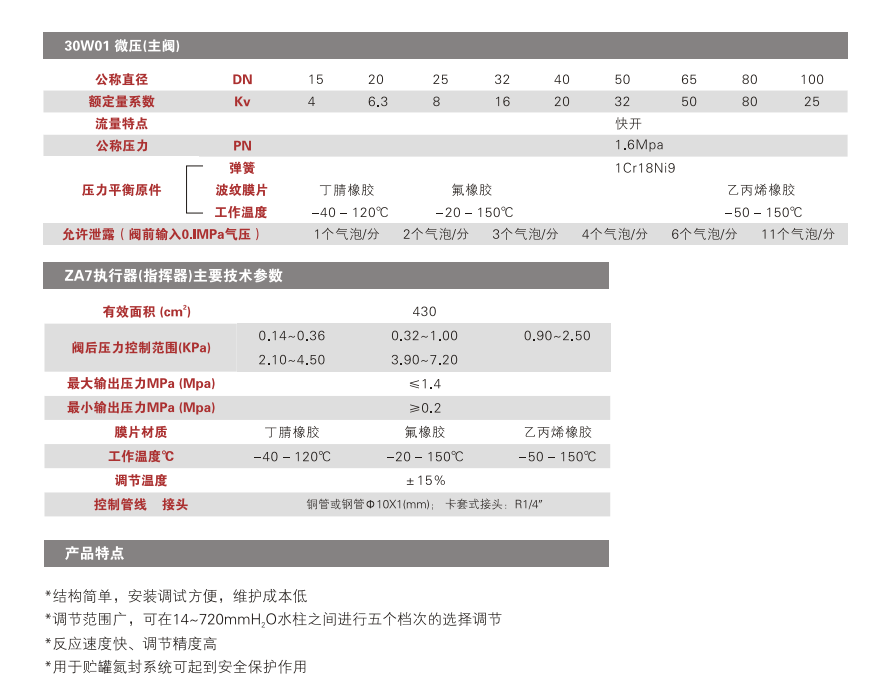

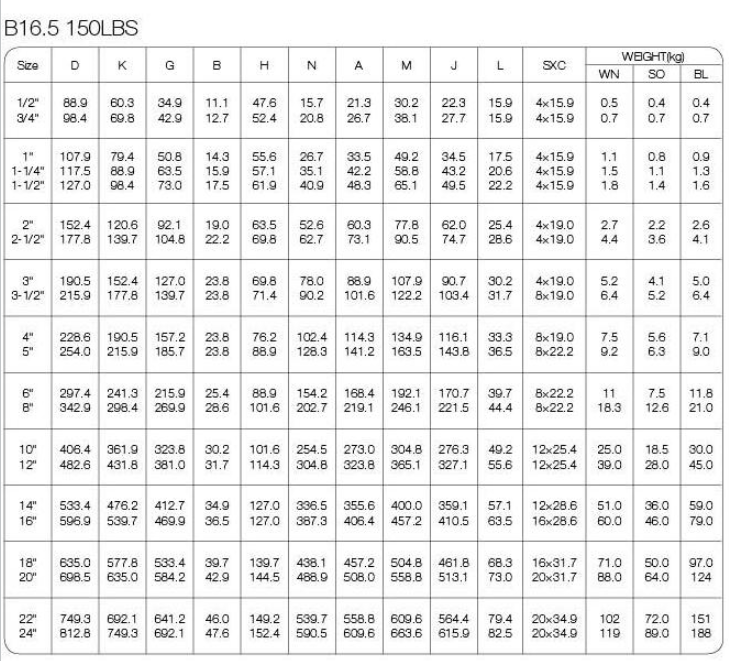

Main performance parameters of YFYT-2 pressure regulator:

Inlet pressure: P1≤320 kilograms per square centimeter

Inlet and outlet pressure difference: P1-P2≤160 kilograms per square centimeter

Flow coefficient: C=5×10-2

Applicable medium: Weakly corrosive and impure liquids

Operating temperature: Room temperature

Pressure characteristics: When P1±40%,ΔP2<0.2 kg/cm ²

Flow characteristic: When Q1±40%, ΔP2<0.3 kg/cm ²

Pipe connection size: Φ8×1.5

Connection method: External thread ferrule connection

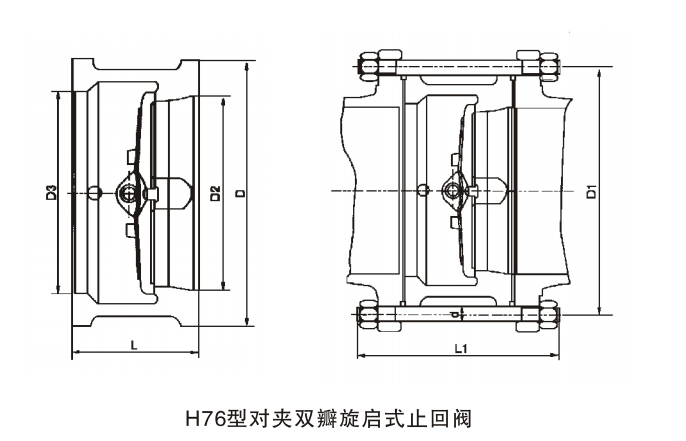

The working principle of YFYT-2 pressure regulator:

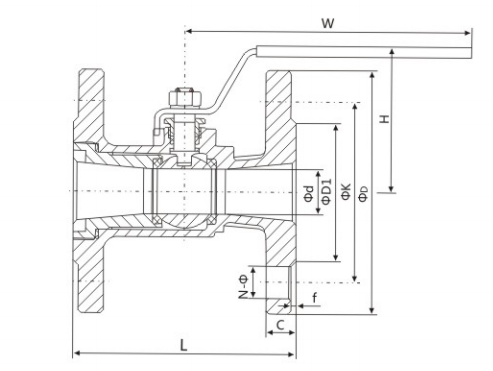

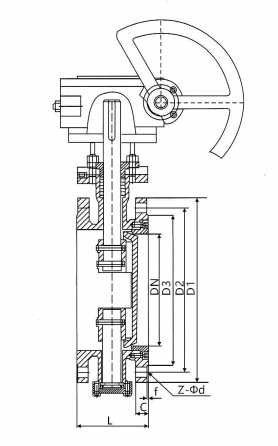

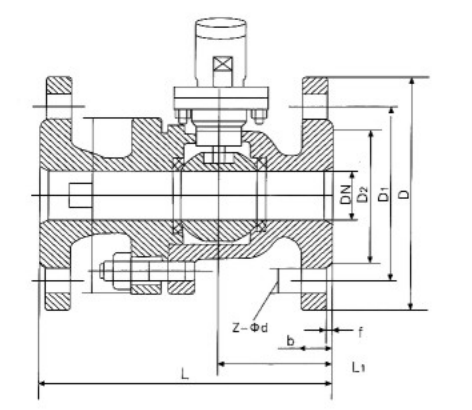

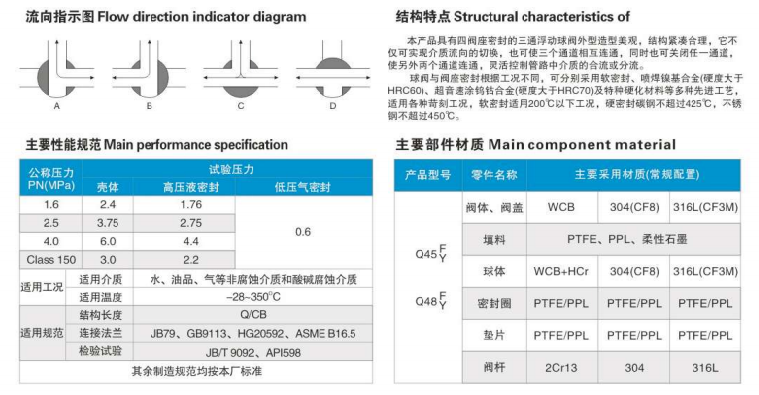

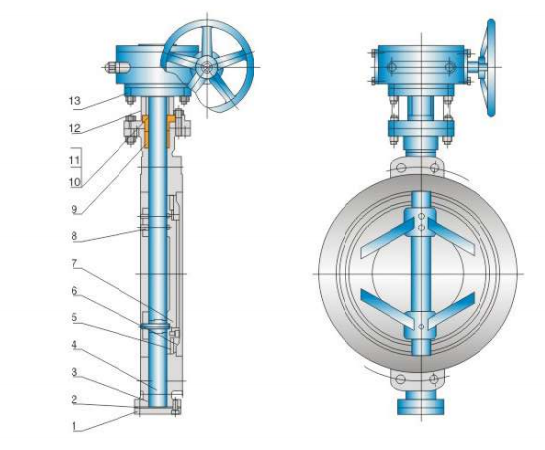

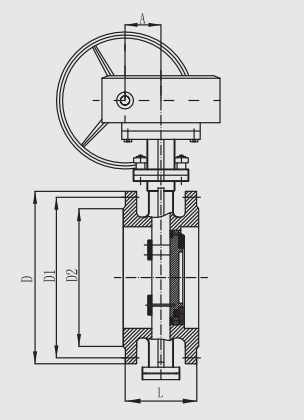

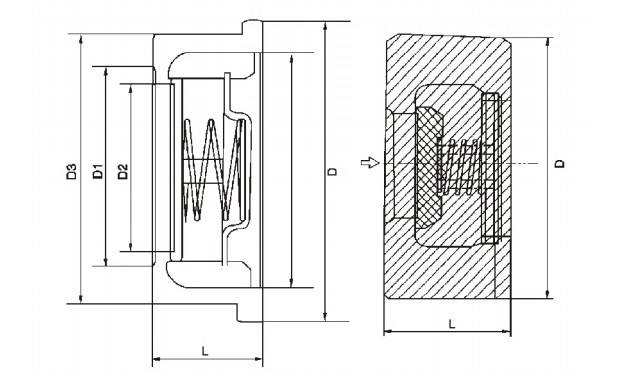

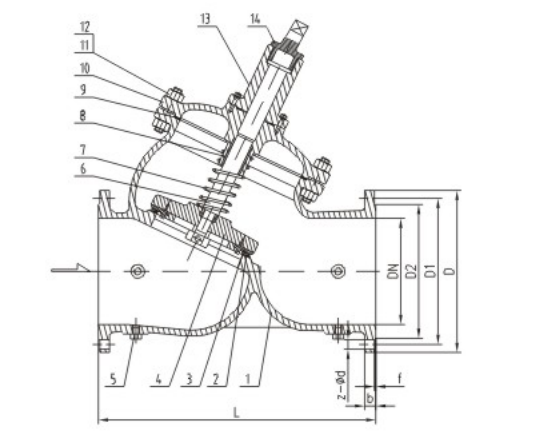

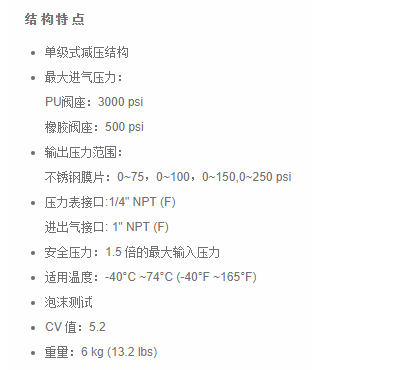

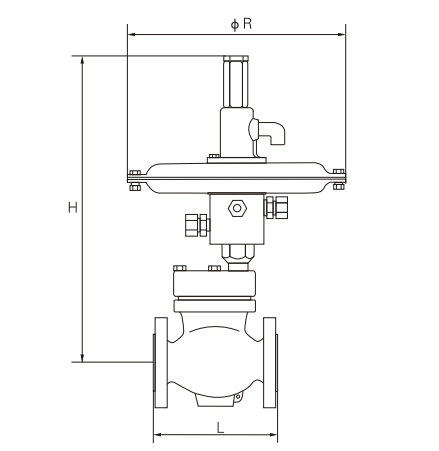

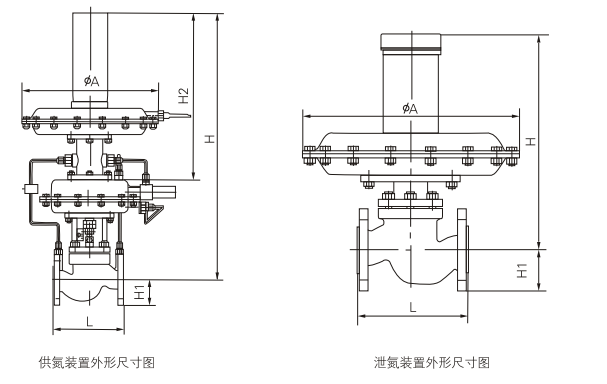

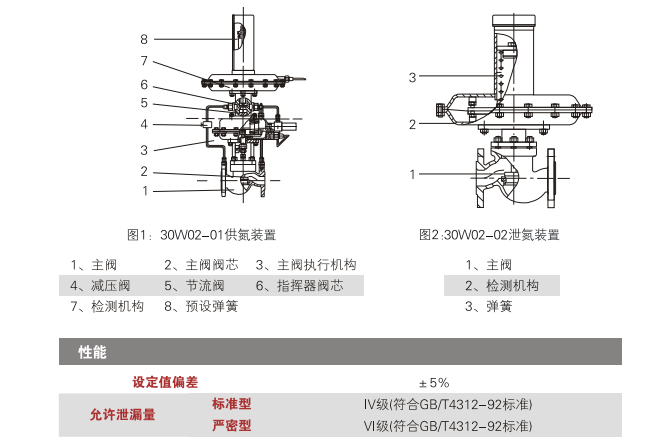

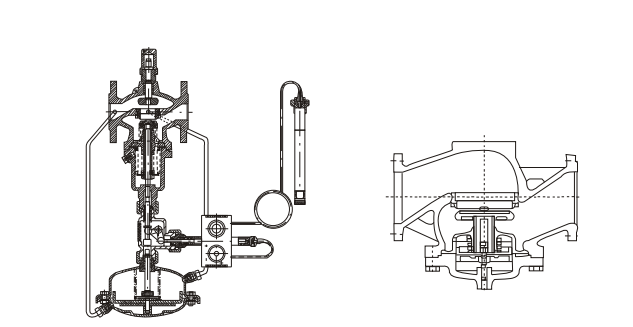

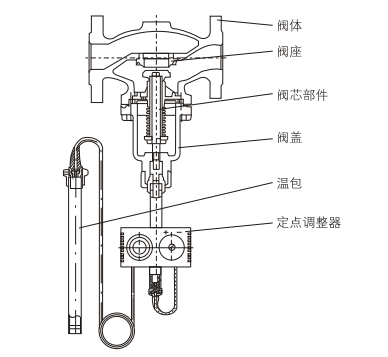

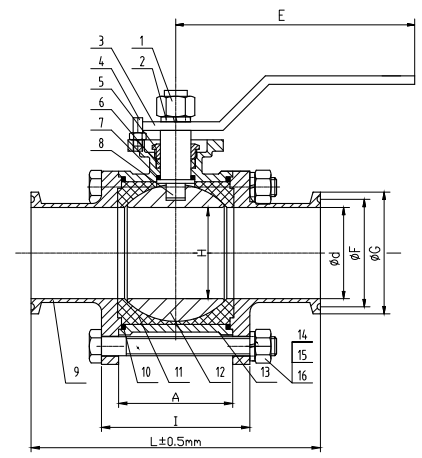

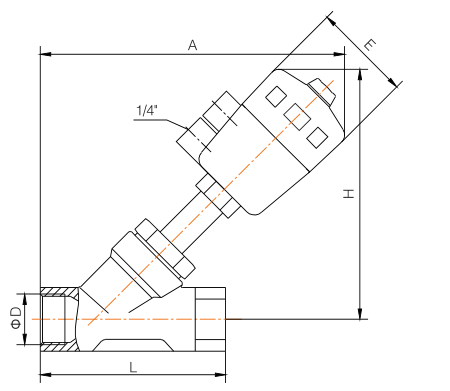

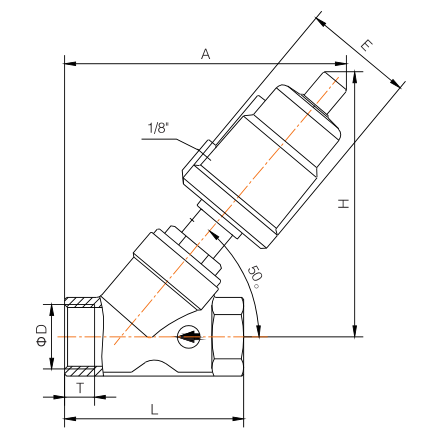

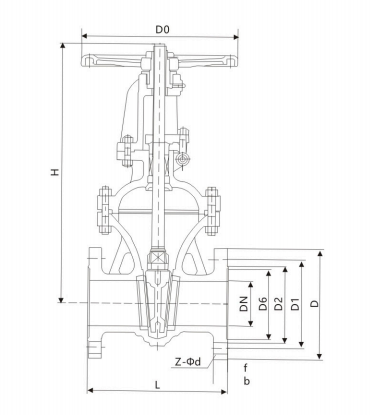

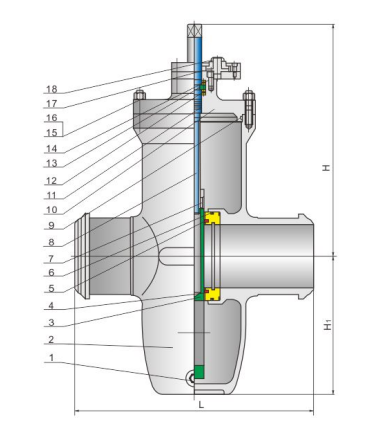

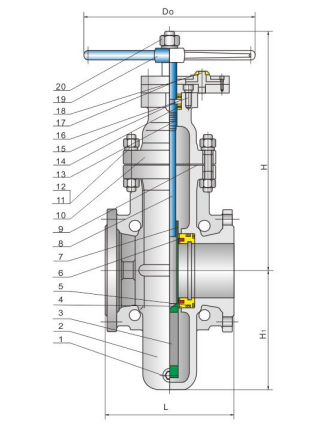

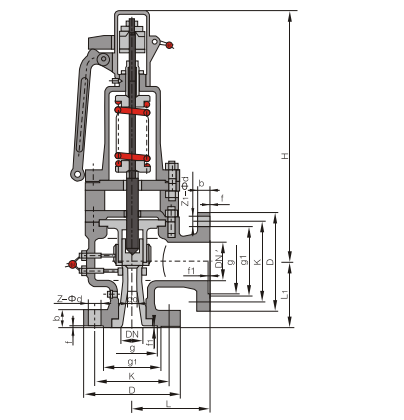

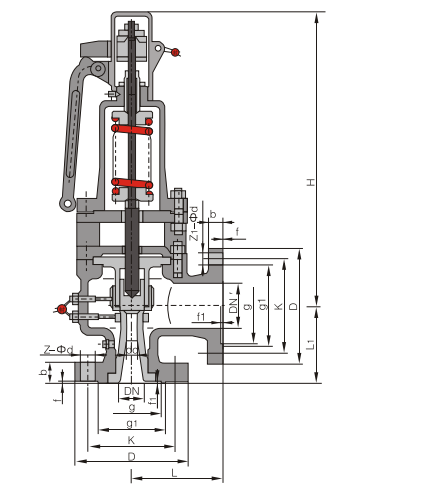

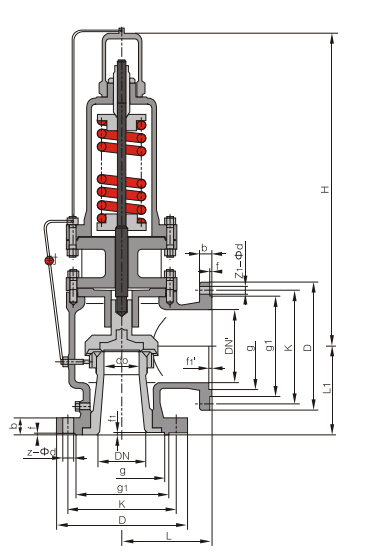

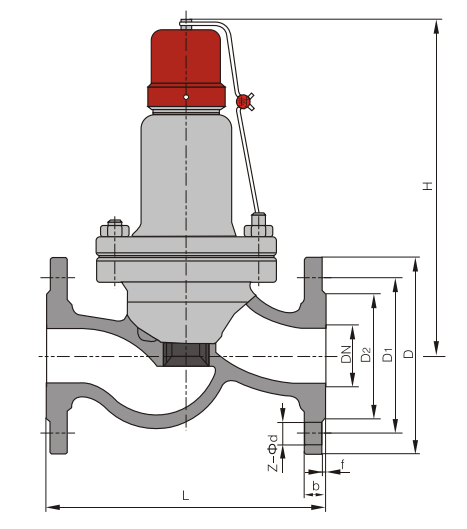

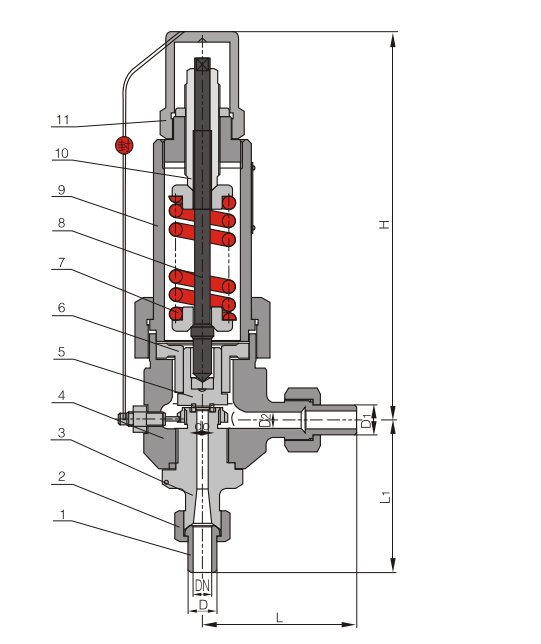

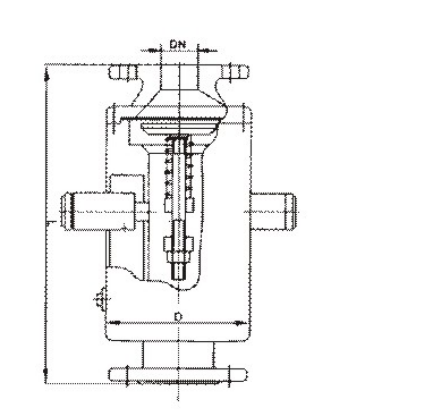

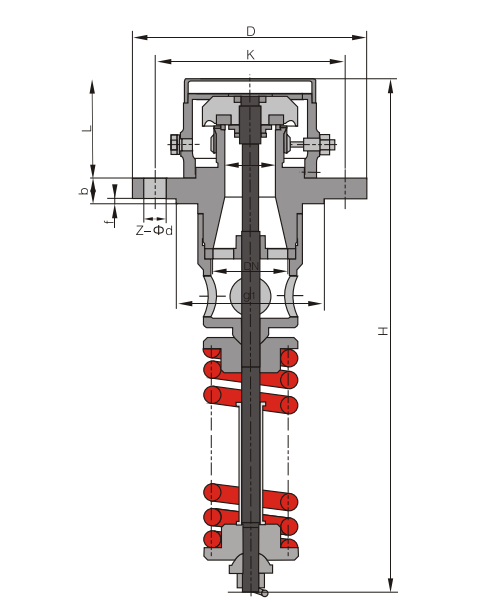

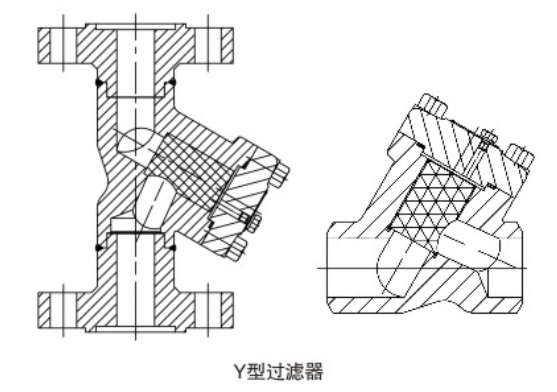

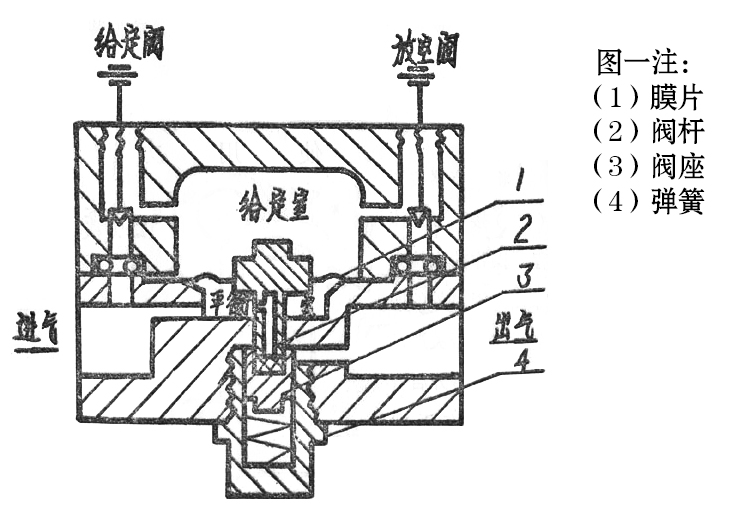

The YFYT-2 type pressure regulator is a direct-acting pressure regulator and is designed based on the principle of force balance. Its principle structure is shown in Figure (1).

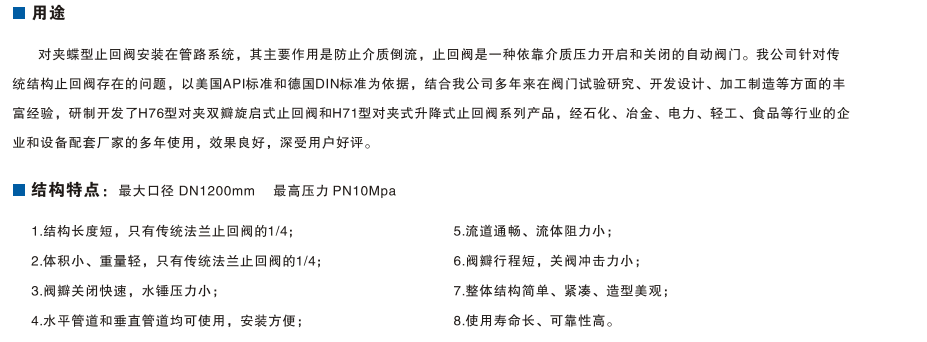

When in use, first close the vent valve, open the set valve, and set the pressure of the set chamber as needed, which is called the set pressure. When the pressure of the device (the device and the balance chamber are connected) is greater than the given pressure, the force below the diaphragm is greater than the force above it, and the diaphragm moves upward. The gas of the device enters the outlet through the small hole of the valve stem. When the pressure of the device gradually decreases to the given pressure, the gas pressure on both sides of the diaphragm is equal, and the diaphragm returns to its original position, and the regulating valve closes automatically. This cycle repeats itself to ensure that the operating pressure of the device is a constant value (with a pressure fluctuation no greater than 0.5 kilograms per square centimeter).

Usage method of YFYT-2 Pressure regulator:

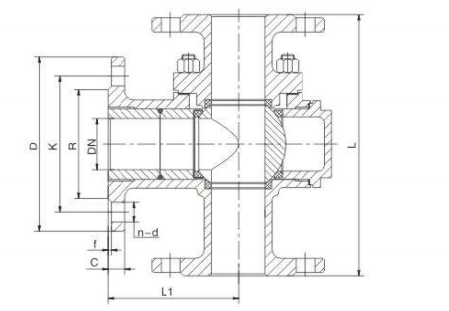

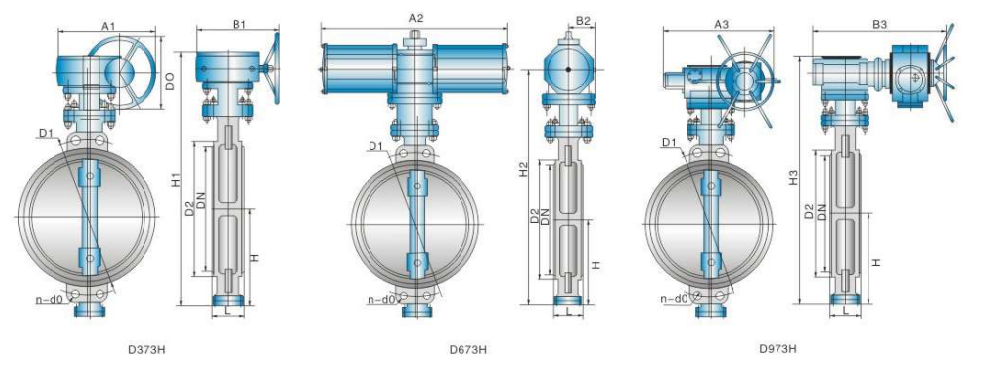

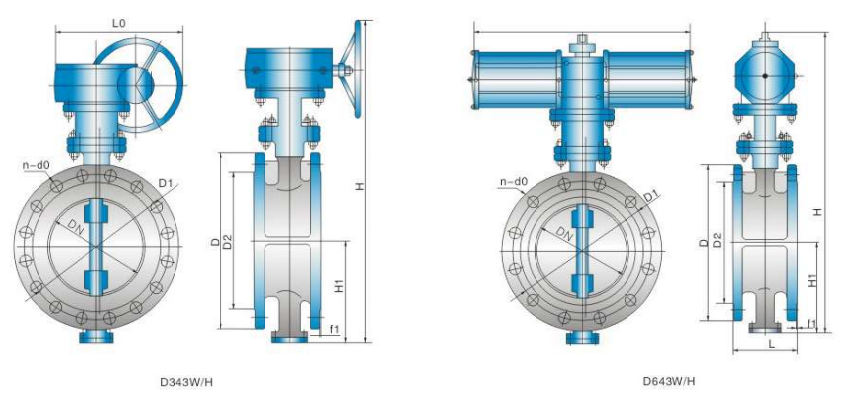

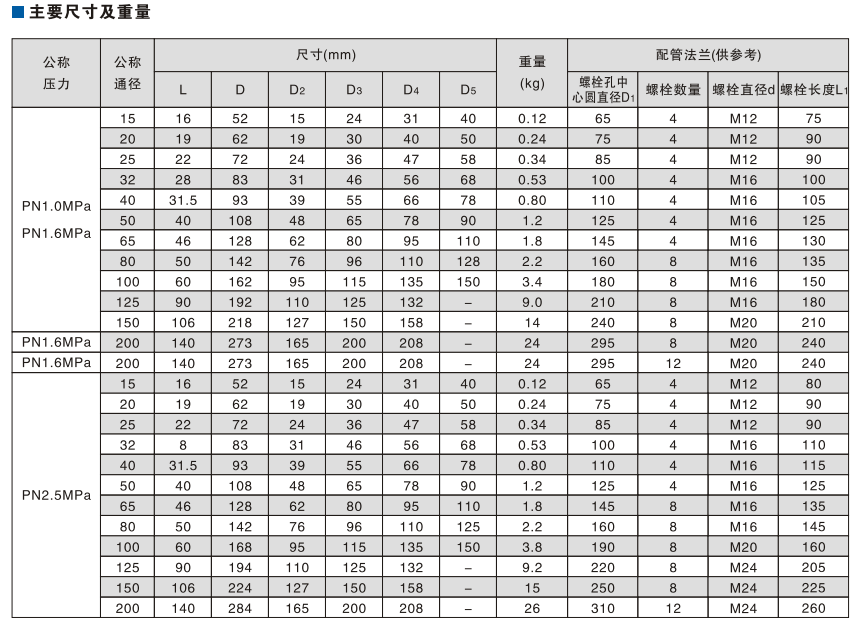

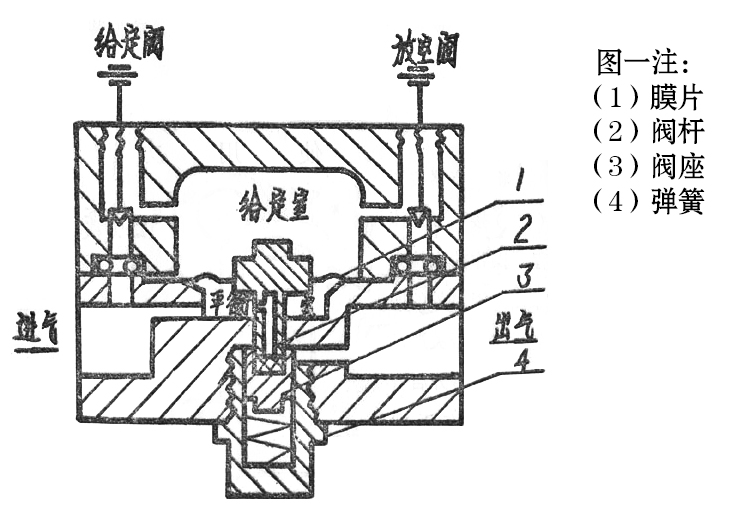

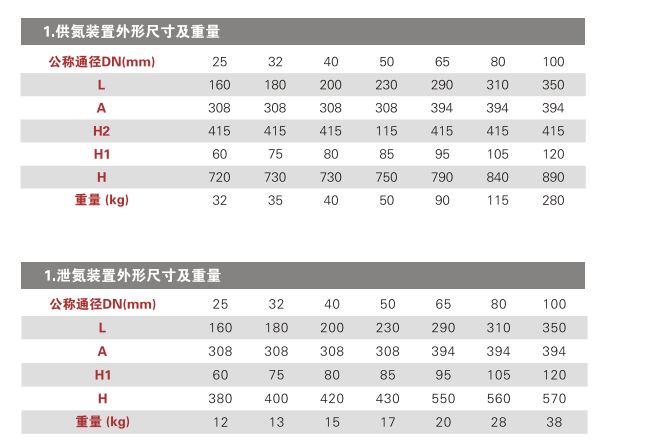

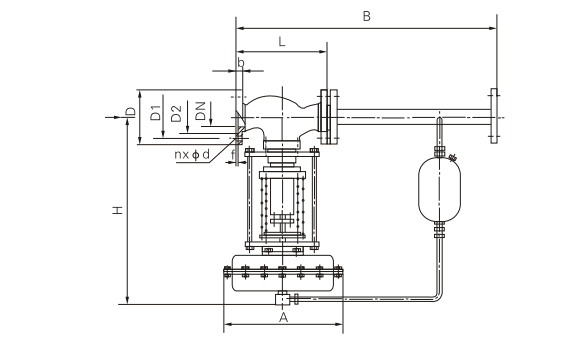

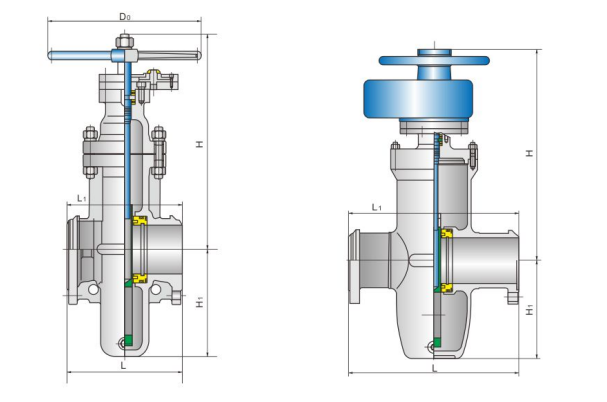

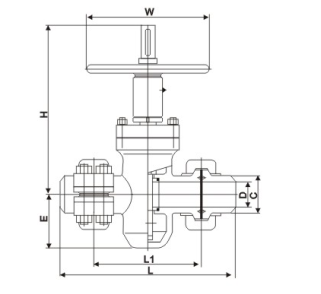

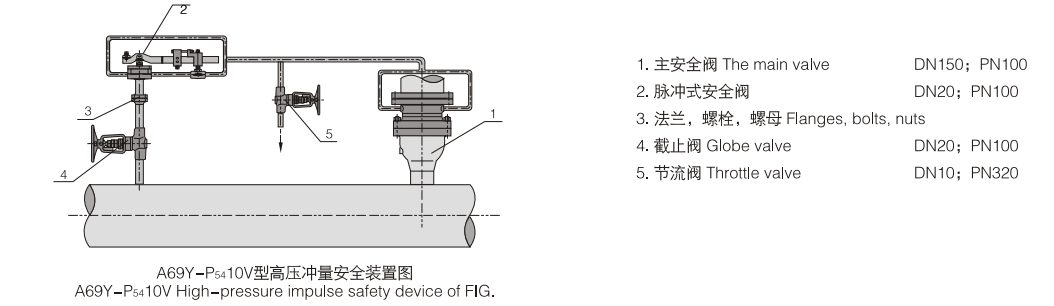

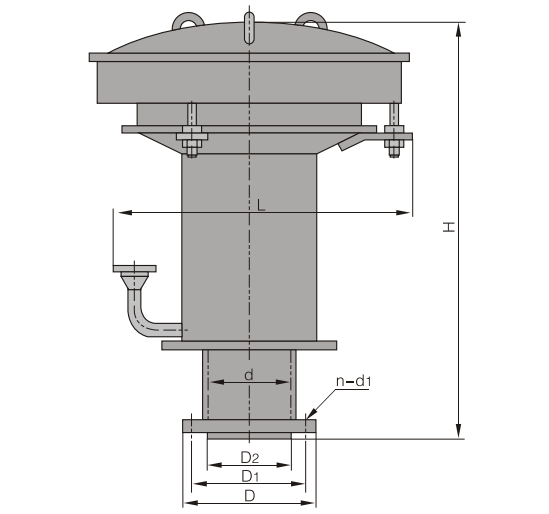

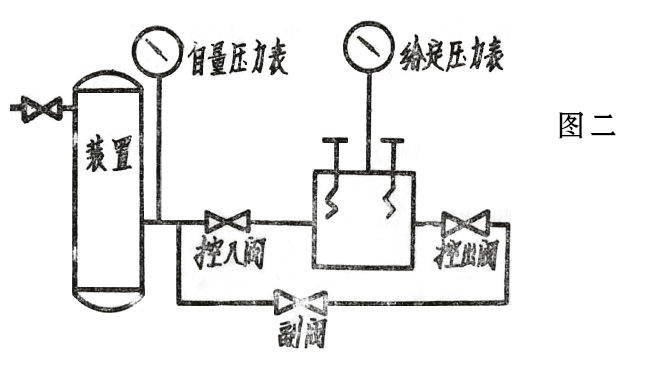

Connect the regulator to the process flow as shown in Figure (2). Before operation, check whether the four valves except the discharge valve are closed tightly, whether the control valve is open, and whether there is any leakage in the pipeline and equipment. Then close the vent valve, open the set valve, and then open the control inlet valve to allow the high-pressure gas to slowly enter the set chamber. At this time, the pressure in the set chamber gradually increases, and the self-measured pressure gradually decreases. When the self-measured pressure reaches the set value, immediately close the set valve. After a few minutes, if the self-measured pressure no longer decreases, it indicates that the regulator is working properly. If the device pressure is not appropriate and is too high, The vent valve can be opened. If it is too low, the set valve can be opened. When not in use, the vent valve should be opened first, and then the control inlet valve should be closed to connect the set chamber and the balance chamber, so that the diaphragm is not affected by the gas pressure difference. Prevent the diaphragm from deforming and affecting the pressure regulation performance. The auxiliary valve is a backup bypass. When the pressure regulator malfunctions, the inlet control valve and the outlet control valve can be closed, and the pressure of the device can be controlled by the auxiliary valve. At this point, the vent valve can be fully opened to release the gas inside the regulator, and then the control valve seat can be replaced or other faults can be eliminated.

Precautions for YFYT-2 Pressure Regulator:

The pressure difference between the inlet and outlet must not exceed 160 kilograms per square centimeter; otherwise, secondary adjustment should be made.

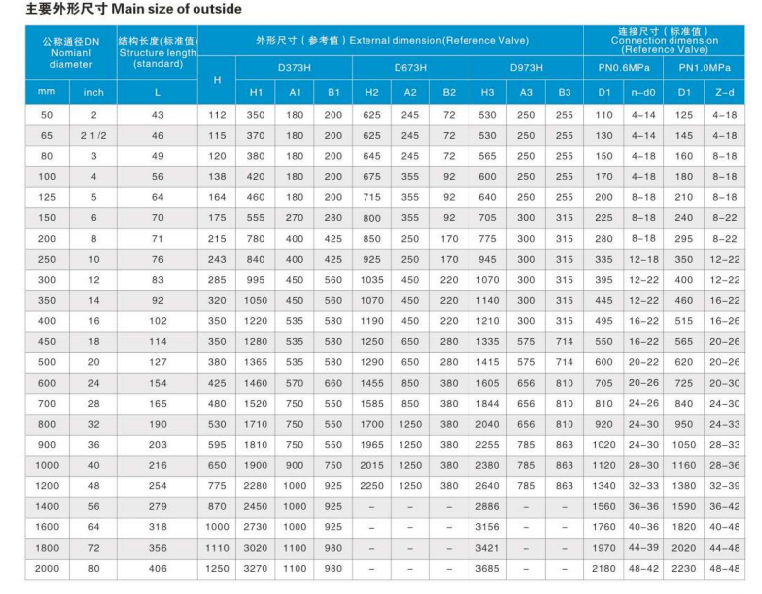

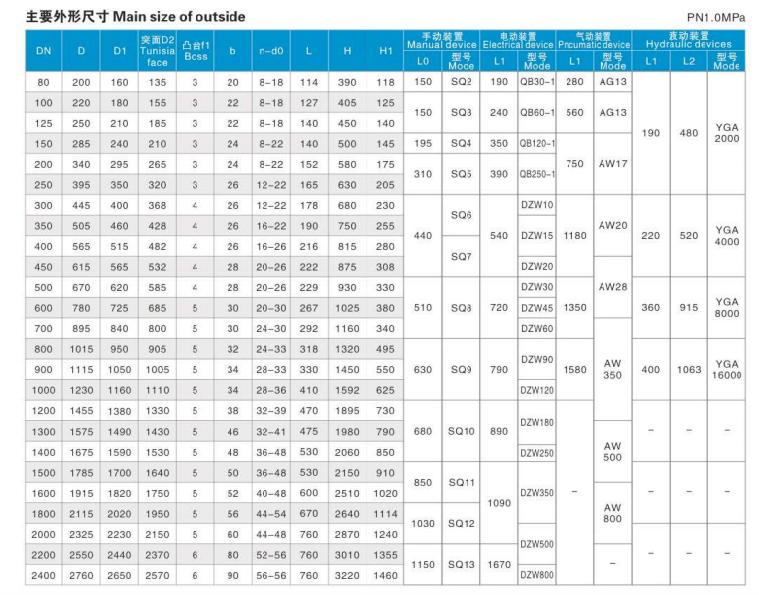

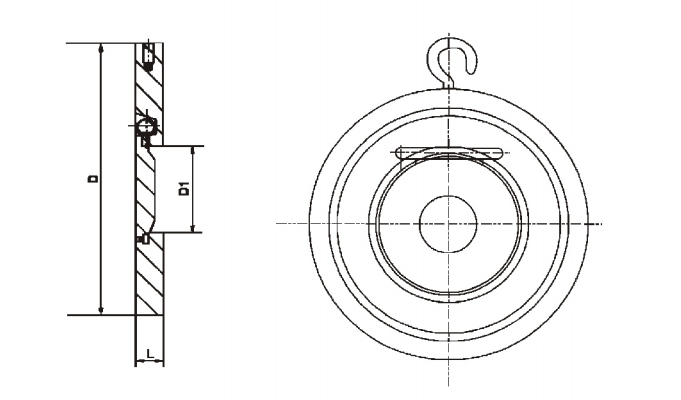

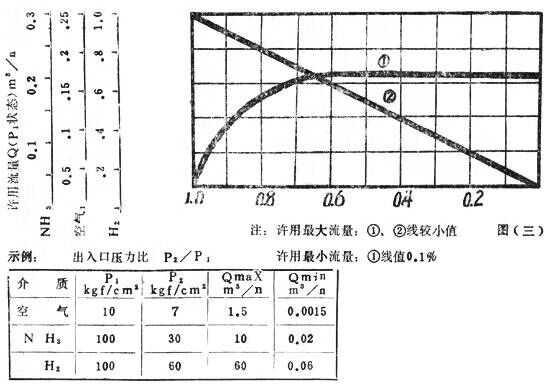

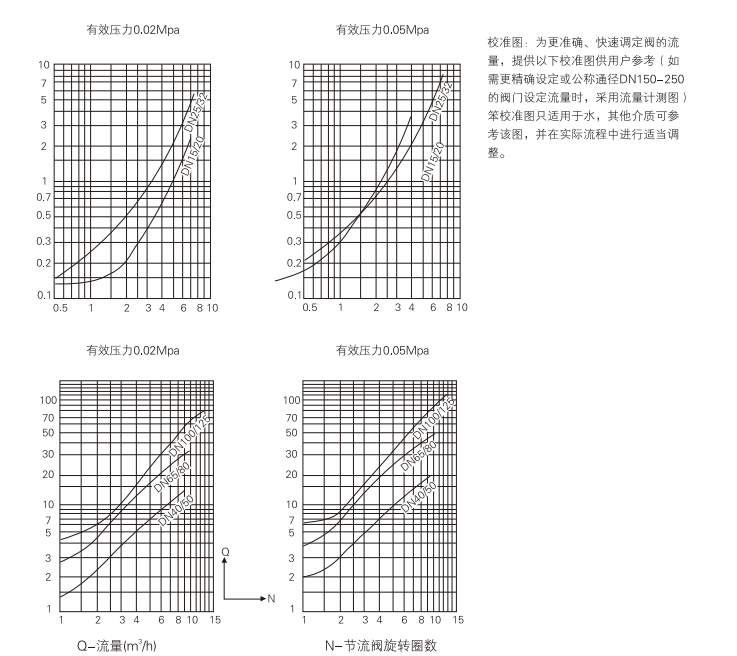

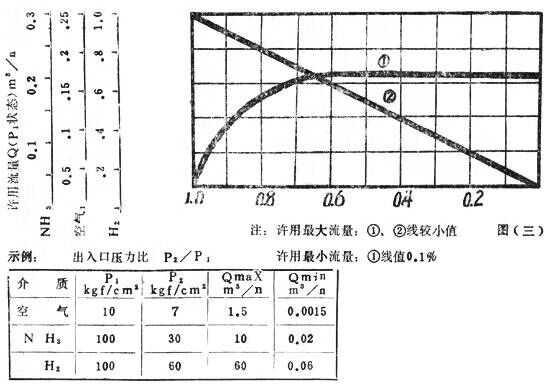

2. The gas flow rate through the regulator is recommended to be selected as shown in Figure (3).

3. The three pressure gauges for input, set and output control should have the same range as much as possible.

The locking torque of the connecting screws between the upper and lower bodies shall not exceed 0.95kg/m. The locking torque of the inlet and outlet joints, pressure gauge joints and valve stem screws shall not be greater than 0.51kg/m.

The gas passing through the regulator must be purified in advance to remove mechanical impurities and liquids.

6. To ensure safety and prevent the stainless steel threads from seizing, do not turn the screws or joints under pressure.

7. The gas filter must not be used. The filter should be cleaned and replaced regularly.

For specific details, please call 021-36376357/36376358 for consultation.