Follow us

The difference lies in the form of the sealing surface of the gate plate. Generally, gate valves often have problems such as water leakage and easy rusting. Ordinary gate valves are generally hard-sealed and are made of cast iron, cast steel or stainless steel. The gate plate of a hard-sealed gate valve is made of metal, and the flow channel has grooves, which can easily accumulate silt and sand, resulting in poor sealing. However, metal sealing has good temperature resistance.

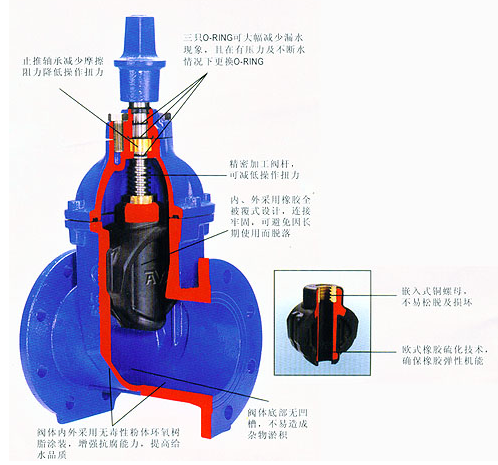

The elastic seat seal gate valve is a type of soft-sealed gate valve. The gate plate is covered with rubber. When the temperature is less than 80 degrees, the flow path is straight without grooves, and no sediment will deposit.

Soft-sealed gate valves (elastic seat sealed gate valves) have a gate plate made of ductile iron lined with rubber, which overcomes the shortcomings of common gate valves, such as poor sealing performance, elasticity fatigue, and easy rusting.

The opening and closing part of the elastic seat seal gate valve is the gate plate. The movement direction of the gate plate is perpendicular to the fluid direction. The gate valve can only be fully open or fully closed and cannot be used for regulation or throttling.

Elastic seat seal gate valves are also known as lift stem gate valves (also called rising stem gate valves). Usually, there are trapezoidal threads on the lifting rod. Through the nut at the top of the valve and the guide groove on the valve body, the rotational motion is converted into linear motion, that is, the operating torque is transformed into the operating thrust. When the valve is opened, the fluid passage is completely unobstructed when the height to which the gate is lifted is 1:1 times the valve diameter. However, during operation, this position cannot be monitored. In actual use, the top point of the valve stem is taken as the mark, that is, the position where it cannot be opened, as its fully open position. To consider the locking phenomenon caused by temperature changes, it is usually opened to the top position and then reversed by 1/2 to 1 turn as the fully open position of the valve. Therefore, the fully open position of the valve is determined by the position of the gate plate (i.e., the stroke).

Elastic seat sealed gate valves can be classified as: exposed stem elastic seat sealed gate valves, concealed stem elastic seat sealed gate valves, underground directly buried elastic seat sealed gate valves, locked elastic seat sealed gate valves, and fire-fighting special elastic seat sealed gate valves, etc. The specifications and models of different types are also different.

Related recommendations