Follow us

The TSS43H series natural gas steam trap is a new type of fully automatic zero-leakage steam trap. This product uses the float ball and lever balance principle to achieve gas-water separation in natural gas mines and automatically discharge the deposited water (liquid) in natural gas storage tanks without other power sources. During the discharge and water (liquid) process, there is no natural gas leakage, and it can adapt to various working conditions. It has the best energy-saving and environmental protection effects.

Structure and working principle

1.The TSS43H type natural gas steam trap uses a "U" structure to form a double chamber inside the valve body, which is a closing system that closes the liquid with the valve and seals the gas with the liquid. At the same time, it changes the flow direction of the medium inside the valve body, making it coincide with the direction of gravity to further separate the liquid and gas, and promotes the sedimentation of residues in the liquid.

2. By using the lever principle, calculate the required power to meet the power conditions of the steam trap during operation.

3. An automatic gas return system is designed based on the principle of a communicating vessel and the density difference of the medium, enabling it to continuously return the gas from the steam trap to the separator during operation, thereby achieving the purpose of continuous and fully automatic operation of the steam trap.

Correct installation

In newly opened well projects, the installation of natural gas steam traps should be carried out after the completion of the main project, the system pressure test and pipeline purging operations. If pressure testing and pipeline purging are conducted after the installation of the steam trap, the natural gas steam trap should be isolated from the system, and the bypass pipeline should be enabled for purging to prevent contamination inside the steam trap.

Maintenance and operation management

When two natural gas steam traps are installed at a steam trap point, under the premise of ensuring sufficient discharge capacity, one should be in operation and the other on standby. Only when the discharge capacity of one trap cannot meet the requirements can both be used simultaneously.

During operation, it is necessary to check whether the system pressure, that is, the inlet pressure of the steam trap, is controlled within the working pressure range of the natural gas steam trap. Overpressure operation is not allowed.

After the system drainage is automated, the main responsibilities of the operators should be to conduct regular inspections, check the movement of the equipment, maintain and service the equipment, record various operation indicators and parameters, and report and handle any abnormal situations in a timely manner if they are found.

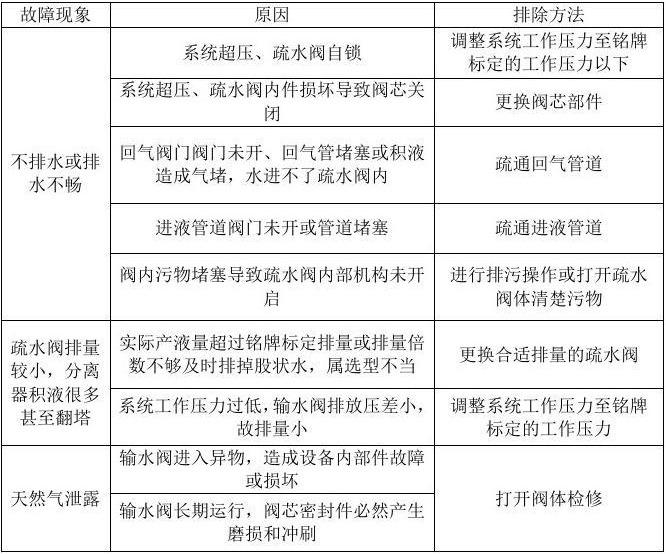

Appendix: Fault Phenomena and Troubleshooting Methods

Shanghai Yifan Valve Manufacturing Co., LTD. 021-36376357, 36376358, 18217676868.

Related recommendations